As the product range grows, this type of storage typically increases in size, resulting in gradually increasing picking and order-picking times that quickly reach over 60/70 seconds per product. With the loads that need to be handled and the strenuous distances the employees have to walk, it is no longer possible to speak of "pleasant working conditions". Increases in costs and error frequency are logical consequences and the warehouse becomes inefficient. These aspects become even more apparent when returned goods are re-stored. Even organisational optimisations such as multi-stage picking do not have much effect.

Similar problems can be observed in spare parts warehouses that supply to production. As a start-up or a small or medium-sized company, one can legitimately raise the question of whether there is an affordable, forward-looking, industry 4.0-imaging solution. The answer, now, is yes!

A new approach

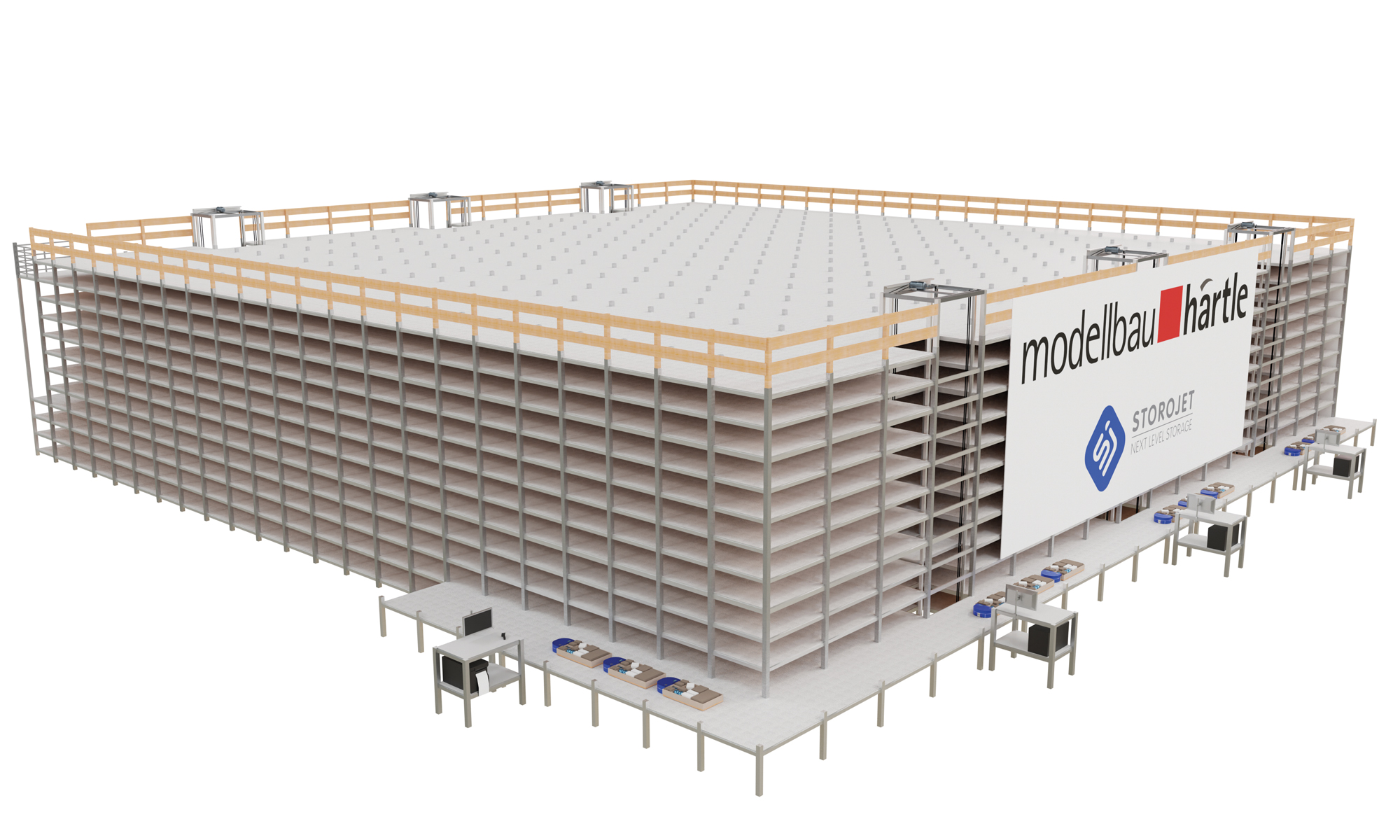

The company Telejet (development), which has been a successful "Innovation Incubator” for over 20 years, has dealt with the particulars of the problem and presents, at the Logimat 2019, in cooperation with ICO Innovative Computer (distribution) an approach, which justifiably claims to be “revolutionary": STOROJET - the world's first automated multi-storey area shelving system.

"Storage" has been rethought - the basic statement has remained: The shelf remains the best solution for storing very heterogeneous products that differ in size, shape, characteristics, look and other parameters.

What characterises a warehouse?

- Defined storage spaces for goods on the shelves.

- Defined transport routes for handling.

- Transport elements to bring goods to the picking.

- Data technology and coding in various forms.

What is a warehouse supposed to achieve?

- A fast, efficient Store-and-Pick

- The fastest possible delivery to customers or the following production stage

- Efficient space utilisation

- Cost-effective picking

- Ergonomically optimal work for the employees

- Energy-saving use of resources

Based on the above requirements, Telejet and ICO have developed a fundamentally new approach based on a core: the Navigation Shelf Board, whose surface is completely printed with coding. Roughly speaking, storage areas and paths can be built in a defined raster format.

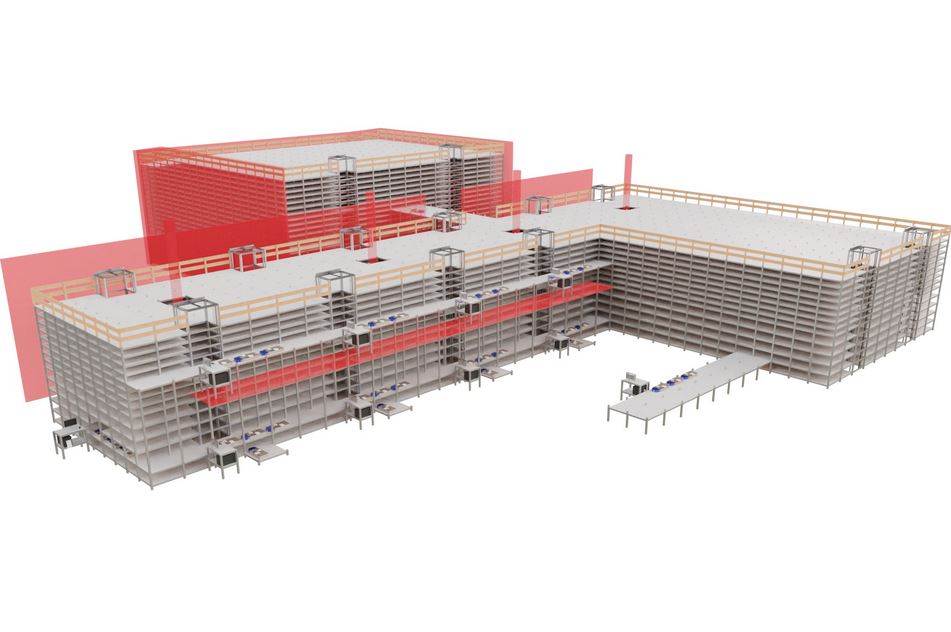

In more detail, this means that in a shelving system up to 12 m in height, with levels mounted one above the other (vertical distance between 32-100 cm), many product carriers are stored closely, moved, coupled and uncoupled using compact storage robots. Depending on the products to be stored, the shelves can be equipped with individual compartments.

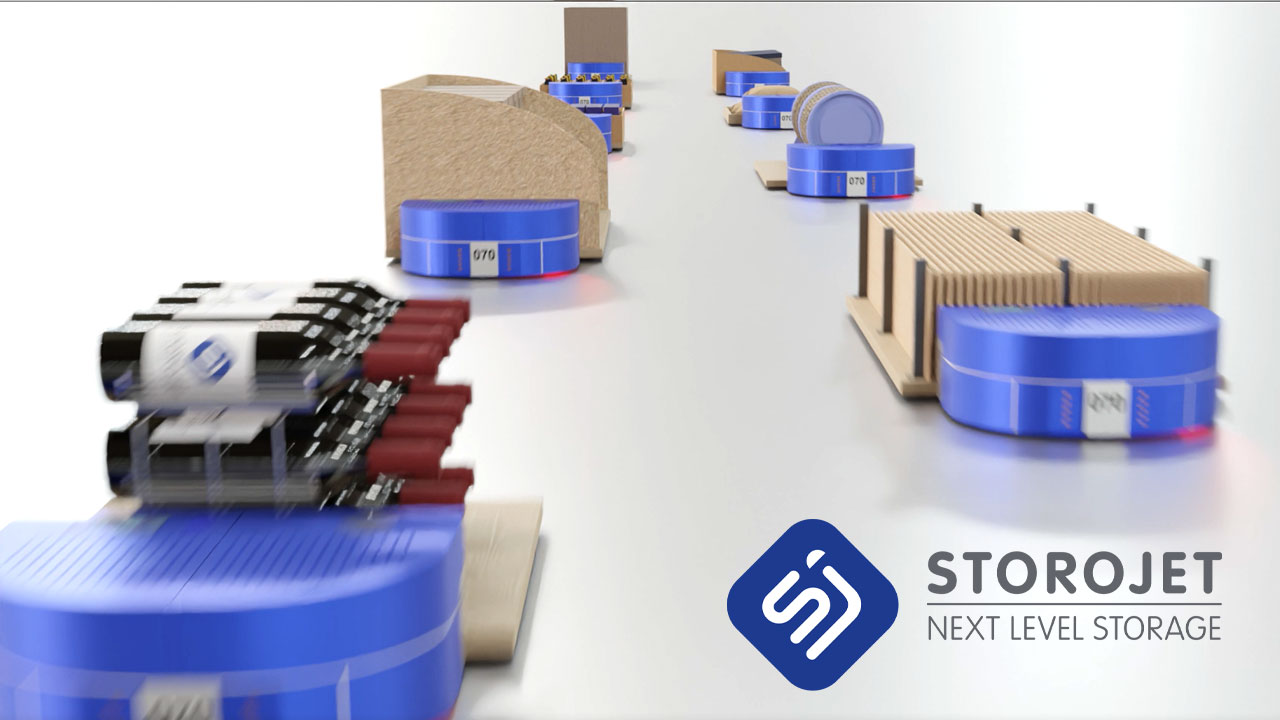

The different levels of the flexible shelving system are connected by several lifts and allow the robots not only horizontal but also vertical mobility. The robots are not rail-bound and can move freely. They orient themselves using the codes on the Navigation Shelf Boards and are coordinated by the central system via radio. The storage robots are the size of a domestic use mowing robot but have far more power and a considerable transport capacity.

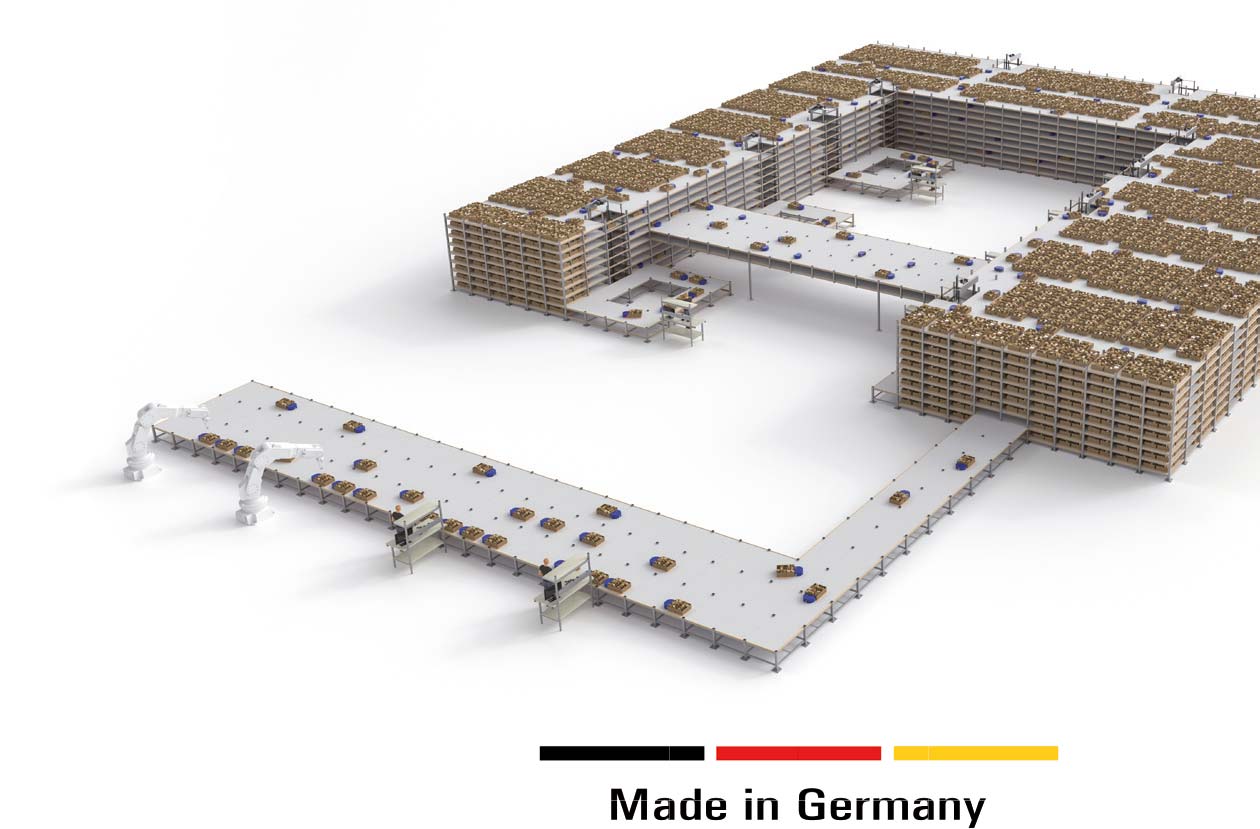

The individual shelving areas, of the self-contained shelving system, have a footprint of 1.2 x 1.6m and are connected by steel columns. On the basis of these floor areas, individual racking systems can now be realised in form and height, depending on the conditions in the warehouse. For example, a U- or L-shape can be designed parallel to a production line in addition to a classic cuboid.

Software is used to define which areas are to be regarded as pathways and which as parking areas.

It is immediately obvious that the STOROJET approach allows a successive warehouse build-up without having to completely replan conveyor lines every time! Compared to ground-based systems, the packing density of the warehouse is directly increased because existing storage areas are always optimally utilised. Nothing stands in the way of a cost-effective modular extension, neither for the shelving nor for the operational robots.

One might argue that the use of automatic storage robots is not a new idea - that's right but size and flexibility make all the difference. Head of Development, Dr. Klaus Jeschke, sums up: "Instead of a pallet, a large box or an entire shelf, our compact STOROJET only brings the "shelf board" with the required goods - this is efficient, fast and saves massive amounts of energy!”

Example of a typical process

To illustrate a whole spectrum of technical intricacies it is necessary to play through a typical sequence.

Thousands of different parts ranging in size from a few centimetres to just under 1 metre - which typically fit on a shelf - are stored in a STOROJET warehouse.

Let's imagine that an order, made up of several products, has been requested.

The picker sees the current packing list on his monitor. Several robots receive the order in advance in order to maintain an uninterrupted flow of goods to people. They travel the distance to the lifts and are lowered to the correct level. They then automatically navigate to the position of the respective goods carriers and dock to them. Using their carriageway, they head back to the assigned output point with the goods carrier and line up at hip height.

The goods to be removed are illuminated directly, in the respective compartment of the goods carrier, by a light sensor (Pick-by-Light) mounted above and only need to be removed. The barcode is scanned by the picker when the article is removed, checked by the system for correctness and then packaged.

With this information, the system knows which storage position is now free and lets the robot return the goods carrier to the storage position and bring the next order. The procedure is the same for the re-storage of returns.

The robot "knows" and controls where to go, which route to use, which warehouse position it needs and to which picking station it is headed for by continually reading and using the codes underneath it as well as the advanced navigation and coordination algorithms.

Even with larger warehouses, this works continuously and almost in less time than it takes to describe the process.

The robot also knows how to help itself: If, for example, an employee moves the goods carrier during storage or retrieval, the robot corrects and uses the codes to find the right path again; even dirt or stains do not confuse it.

As there are always several robots in continual use, a regular flow of goods is achieved that functions quickly and reliably and largely supports or relieves employees. Depending on the required load, the system can be scaled by the robots during operation. If required, the robots recharge their long-lasting energy reserves themselves during operation at permanently installed charging points and report directly back to duty.

This new approach leads to an automated storage system with multidimensional flexibility: from space utilisation to heterogeneity of goods to scaling in shift operation and fault tolerance - and all this in a price range which allows small and medium-sized companies.to implement it into their projects.

At the picking station, the goods carriers convince with a further trend-setting feature. They are completely accessible from above and thus offer the best conditions for using fully automatic robot arms (manipulators) for the picking process depending on the user's requirements.

If this step is taken, the developers are convinced that it is even possible to reduce human picking times by 100%.

Side effects

In addition, there are other positive side effects such as a significantly less time-consuming and in some cases even genuine continuous "inventory at the touch of a button". There is also improved anti-theft protection because nobody can reach into the deeper interior of the shelving system and the visible external surfaces do not reveal what they contain. As there is only one access point to the warehouse, process reliability is increased and the necessary documentation is simplified - follow-up costs are reduced. The amount of training required for this new system is minimal and discussions about a "structured or chaotic warehouse" become obsolete. Since the robot only picks up and brings the required goods, time-consuming and energy-consuming "rearrangement" is no longer necessary.

Much more than prototype status

It is crucial to note that we are not talking about a feasibility study or a prototype status here. Such a warehouse, at our partner Speedy GmbH, has impressively proven its capabilities for over 2 years of productive operation.

We recommended watching this system live or to get comprehensive advice from the developer.

Cookies & Privacy

Cookies & Privacy